Product Description

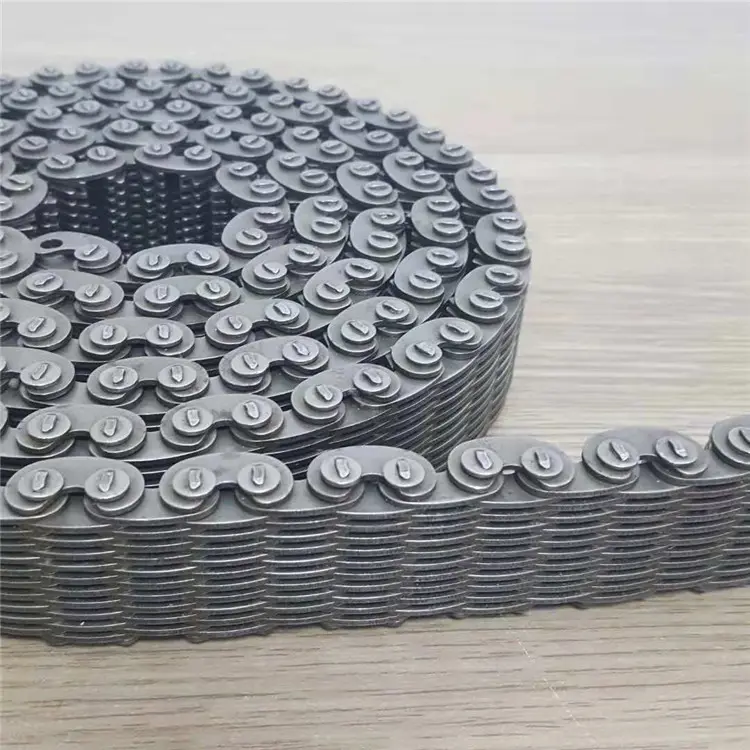

Motorcycle Part High Quality Timing Chain for Pulsar 135ls

FEATURE:

| OUMURS CODE | 10110401801 |

| Fits For | Pulsar 135ls |

| Package | Specific box |

| Delivery date | 20~30 Working Days |

Other Motorcycle Parts We Can Offer:

| Big Engine Brand: | HARLEY DAVIDSON, BMW, DUCATI, KAWASAKI, KTM, TRIUMPH, CFMOTO, SUKADI, HYOSUNG, POLARIS, etc. |

| Other Motorcycle Brand: | HONDA, YAMAHA, SUZUKI, BAJAJ, KEEWAY, KYMCO, CHINAMFG , TVS, LONCIN, ZONGSHEN, SHINERY, HangZhou, DAYANG, XIHU (WEST LAKE) DIS.N, XIHU (WEST LAKE) DIS., HAOJIN, HAOJUE, QINGQI, XIHU (WEST LAKE) DIS., PIAGGIO, PEUGEOT, VESPA, AKT, AYCO, BERA, DAYTONA, FACTORY, GENESIS, GILERA, MOTOMEL,YUMBO, ZANELLA, etc. |

| Big Engine Models: | MONSTER, Softail, Dyna, Touring, Sportster, ZX, ZR, ZG, ZZR, GPR, GPZ, NINJIA, VERSYS, DAYTOAN,etc. |

| Other Motorcycle Models: | AX, ACE, AN, AKT, ARN, AYCO, ARSEN, AVENGER, AGILITY, BIZ, BWS, BROS, BEST, BOXER, CA, CB, CD, CG, CH, CM, CGL,CBF, CBR, CBX, CRF, CRM, CARGO, CUSTOM, CYGNUS, DS, DL, DR, DUKE, DAKAR, DISCOVER, EN, FZ16, FT, FLY, FOX, FAZER, FIDDLE, GN, GS, GY6, GSF, GSR, GSX, GSXR, HORSE, JL, JH, JOG, JET4, JOYLIE, LOGIC, LIBERO, MP3, MAX, MBK, MOTARD, NXR, OWEN, ORBIT, OUTLOOK, PCX, PLATINO, PULSAR, QJ, RX, RTX, RKS, RE Tricycle, ROCKZ, SV, SH, SMR, SKUA, SPORT, SPEED, SILVERBLADE, TX, TMAX, TITAN, TYPHOON, VLM, VICTOR, WY, WAVE, XY, XT, XV, XV, XCD, XRE, YB,YP, YBR, YZF, YFM, etc. |

FAQ:

1. How soon can I get the quotation?

Re: The quotation should be given within 24 hours .

If it is very urgent, pls make direct contact with CHINAMFG sales.

2. How to get the best price from OUMURS?

Re: The bulk order price can be negotiated.

We will quote the latest best price according to the customer final purchase list.

3.Can I get a sample to check your quality?

Re: Sure! For most product sample for free, but all other cost need to pay by customer.

Freight will be returned in first order.

4. Can CHINAMFG do the packages as we need?

Re: Sure for bulk order!.

For others, we will offer OUMURS, TWOM or neutral pack for you.

For long term relation, can be negotiated with customized pack

Thx for Reading!

To know more about OUMURS, kindly visit oumurs .

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Chain |

|---|---|

| Material: | Steel |

| Certification: | ISO9001:2001 |

| Number of Row: | Double Row |

| Market: | South America; Middle America; Mexico; India |

| Transport Package: | Packed by Specific Box |

| Samples: |

US$ 2.5/Piece

1 Piece(Min.Order) | |

|---|

What are the signs of wear and tear in a motor chain?

Over time, a motor chain can experience wear and tear due to usage, environmental factors, and lack of proper maintenance. It’s important to monitor the condition of the motor chain regularly to identify signs of wear and address them promptly. Here are some common signs of wear and tear in a motor chain:

1. Chain elongation: One of the most noticeable signs of wear in a motor chain is elongation. The chain may appear longer than its original length due to stretching and wear of the pins, bushings, and rollers. Excessive chain elongation can cause poor performance, increased noise, and affect the overall efficiency of the system.

2. Increased chain noise: As a motor chain wears, it can produce more noise during operation. Excessive noise can indicate worn-out or damaged components, such as pins, bushings, or rollers. It’s important to investigate and address the source of the noise to prevent further damage and ensure smooth operation.

3. Chain slack or looseness: If the motor chain exhibits excessive slack or looseness, it may indicate wear and elongation. Proper tension is essential for the efficient transfer of power, and a loose chain can cause slippage and decreased performance.

4. Visible signs of damage: Inspect the motor chain visually for any visible signs of damage, such as broken links, cracked plates, or worn-out pins and bushings. These signs indicate significant wear and may require immediate attention or replacement of the chain.

5. Uneven wear: Uneven wear patterns on the chain’s components, such as unevenly worn pins or bushings, can indicate misalignment or other issues. Identifying and addressing the cause of uneven wear is crucial to prevent further damage and ensure proper chain performance.

Regular inspection and maintenance can help identify these signs of wear and tear in a motor chain. If any of these signs are observed, it is recommended to consult a professional or the chain manufacturer for further evaluation and guidance on appropriate maintenance or replacement.

Can a motor chain handle heavy loads?

Yes, motor chains are designed to handle heavy loads in various applications. Here are some factors to consider:

1. Chain Strength: Motor chains are available in different strength ratings, typically measured in terms of their maximum allowable tension or breaking strength. It is important to select a motor chain with a strength rating suitable for the anticipated loads in your application. Chains with higher strength ratings can handle heavier loads.

2. Chain Material: Motor chains are commonly made from high-strength steel or alloy materials that provide excellent durability and load-bearing capacity. The choice of material depends on the specific application requirements, including the expected load, environmental conditions, and any regulatory standards.

3. Chain Design: Motor chains designed for heavy-load applications often have robust construction features to enhance their load-carrying capabilities. These may include larger pitch sizes, thicker plates, hardened components, and precision manufacturing. The design ensures that the chain can withstand the forces and stresses associated with heavy loads.

4. Lubrication: Proper lubrication is essential for motor chains handling heavy loads. It helps reduce friction and wear, ensuring smooth operation and extending the chain’s service life. Adequate lubrication also prevents overheating and corrosion, which can negatively impact the chain’s load-carrying capacity.

5. Sprocket Design: The sprockets that engage with the motor chain also play a crucial role in handling heavy loads. Sprockets should be designed to evenly distribute the load across the chain and provide reliable engagement. Robust and properly sized sprockets ensure that the chain can effectively transmit the heavy loads without excessive wear or failure.

When considering a motor chain for heavy-load applications, it is important to consult the manufacturer’s specifications and guidelines. They can provide detailed information on the chain’s load-carrying capacity, including factors such as tensile strength, working load limits, and recommended safety factors. Proper chain selection, regular maintenance, and adherence to load limitations are key to ensuring safe and efficient operation under heavy loads.

How does a motor chain differ from a regular chain?

A motor chain, also known as a power transmission chain, differs from a regular chain in terms of its design and purpose. Here are the key differences:

1. Load Capacity: Motor chains are specifically designed to handle higher loads compared to regular chains. They are built to transmit power and motion between different components in mechanical systems.

2. Precision and Accuracy: Motor chains often have precise tooth profiles or roller systems that ensure accurate positioning and synchronization of components. This is important in applications such as engines, where precise timing is critical.

3. Durability and Strength: Motor chains are built to withstand heavy loads, high speeds, and continuous operation. They are constructed using high-quality materials and advanced manufacturing techniques to ensure durability and strength.

4. Lubrication and Maintenance: Motor chains may require specific lubrication to reduce friction and wear, ensuring smooth operation. Regular maintenance, such as periodic inspection and lubrication, is important to keep the chain in optimal condition.

5. Application-Specific Design: Motor chains are designed for specific applications, such as power transmission in engines, conveyor systems, or lifting equipment. They are engineered to meet the unique requirements of these applications, considering factors such as load capacity, speed, environment, and operational conditions.

It’s important to note that while motor chains are designed for specific applications, they may have similarities with regular chains in terms of basic construction and functionality. However, motor chains are engineered to handle higher loads, provide precise motion transmission, and ensure reliable performance in demanding industrial settings.

editor by CX 2024-04-11