Product Description

ZheJiang CHINAMFG Machinery Co.,Lt : a professional manufacturer of industry conveyor and accessories in China.

Service: customize conveyor equipment according to the buyers’ drawings and requirements, supply conveyor spare parts, and packing machine accessories. If you want to learn more details, please write to us.

Customized conveyors: modular belt conveyor, top chain conveyor, plastic flexible chain conveyor, spiral conveyor, gripper conveyor, inclined belt conveyor, PU/PVC belt conveyor, roller conveyor etc.

Spare parts: modular belt,flexible plastic chain,plastic top chain,steel top chain,roller,levelling feet,guardrail/guide,bracket,sprocket,wear strip etc.

Applications: food, beverage, electronics, tobacco, chemical, pharmaceutical, logistics, and other industries.

Maxsen can provide a proffesional transmission solution, which is combined with suitable type conveyors into a complete conveyor line system based on the handling materials and project budgets of the customers.

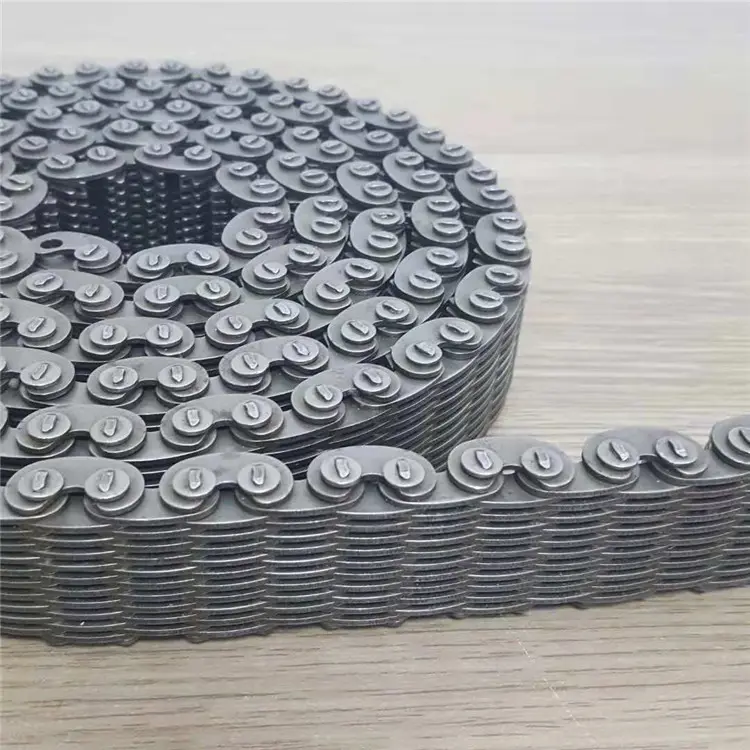

Plastic Flexible Chain Conveyor System

Flex chain link conveyor is with stronger flexibility on the delivery of a conveyor system.Automatic transmission in the future is a potential infinite products using a wide range and suitable for any size of the venue.Conventional transmission line is also good,but if it is L-shape or O shape line, there needs particularly high requirements for angles.Angle is too small,the conveyor line is unable to make with belts, chain plates, modular belt, roller so that it can meet the R angle size.Flexible chain conveyor can do 200 R Angle. Super quiet and easy to maintain.

Products:turning flexible conveyor,linear flexible conveyor, separation of flexible conveyor,circle shape flexible conveyor, climbing flexible conveyor, spiral flexible conveyor.

Material classification of toothed chain plate: white POM, mixed anti-static material black.

Body material:aluminum profile.

Assembly method: put the toothed chain plate in the middle of the profile chute, and adopt the flexible special drive head and drive tail.

Driving mode: the reducer drives the axle diameter rotation gear to pull the chain plate.

The Angle of the flexible conveyor is relatively flexible.

Why Choose US

Q1. Are you trading company or manufacturer?

A: We’re manufacturer. We have our own factory and experienced technicans.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery and delivery time?

A: EXW, FOB, CFR, CIF, DDU, etc.

Generally, it will take7 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q5. What is your sample policy?

A: We can supply some certain small sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

For more details, please write to us. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Online Support and Supply Conveyor Parts |

|---|---|

| Warranty: | 1 Year |

| Structure: | Chain Conveyor |

| Material: | Stainless Steel |

| Material Feature: | Heat Resistant |

| Application: | Chemical Industry, Grain Transport, Power Plant |

| Samples: |

US$ 150/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can a motor chain be used in vertical motion applications?

Yes, a motor chain can be used in vertical motion applications. Vertical motion refers to applications where the chain is responsible for lifting or lowering loads vertically. Motor chains are commonly used in various vertical motion systems, such as elevators, vertical conveyors, lifting mechanisms, and overhead cranes.

When using a motor chain for vertical motion, it is important to consider the following factors:

1. Load Capacity:

Ensure that the motor chain has sufficient load-carrying capacity to handle the weight of the load being lifted or lowered. It is crucial to select a chain with a suitable working load limit to ensure safe and efficient operation.

2. Tensioning and Alignment:

Proper tensioning and alignment of the motor chain are critical in vertical motion applications. The chain should be adequately tensioned to prevent excessive slack or sag, which can affect its performance and increase the risk of derailment.

3. Safety Mechanisms:

Implement appropriate safety mechanisms, such as limit switches or overload protection devices, to ensure safe operation and prevent accidents in vertical motion applications. These mechanisms help detect and respond to abnormal conditions, such as excessive load or chain tension.

4. Lubrication and Maintenance:

Regular lubrication and maintenance are essential for the proper functioning and longevity of the motor chain in vertical motion applications. Ensure that the chain is properly lubricated to minimize friction and wear.

5. Compliance with Regulations:

Ensure that the motor chain and associated components comply with relevant safety and industry regulations for vertical motion applications. This includes adherence to standards and guidelines for load capacity, materials, design, and installation.

By considering these factors and following proper installation and maintenance practices, a motor chain can be effectively used in vertical motion applications, providing reliable and efficient performance.

Can a motor chain handle heavy loads?

Yes, motor chains are designed to handle heavy loads in various applications. Here are some factors to consider:

1. Chain Strength: Motor chains are available in different strength ratings, typically measured in terms of their maximum allowable tension or breaking strength. It is important to select a motor chain with a strength rating suitable for the anticipated loads in your application. Chains with higher strength ratings can handle heavier loads.

2. Chain Material: Motor chains are commonly made from high-strength steel or alloy materials that provide excellent durability and load-bearing capacity. The choice of material depends on the specific application requirements, including the expected load, environmental conditions, and any regulatory standards.

3. Chain Design: Motor chains designed for heavy-load applications often have robust construction features to enhance their load-carrying capabilities. These may include larger pitch sizes, thicker plates, hardened components, and precision manufacturing. The design ensures that the chain can withstand the forces and stresses associated with heavy loads.

4. Lubrication: Proper lubrication is essential for motor chains handling heavy loads. It helps reduce friction and wear, ensuring smooth operation and extending the chain’s service life. Adequate lubrication also prevents overheating and corrosion, which can negatively impact the chain’s load-carrying capacity.

5. Sprocket Design: The sprockets that engage with the motor chain also play a crucial role in handling heavy loads. Sprockets should be designed to evenly distribute the load across the chain and provide reliable engagement. Robust and properly sized sprockets ensure that the chain can effectively transmit the heavy loads without excessive wear or failure.

When considering a motor chain for heavy-load applications, it is important to consult the manufacturer’s specifications and guidelines. They can provide detailed information on the chain’s load-carrying capacity, including factors such as tensile strength, working load limits, and recommended safety factors. Proper chain selection, regular maintenance, and adherence to load limitations are key to ensuring safe and efficient operation under heavy loads.

What are the applications of motor chains in various industries?

Motor chains, also known as power transmission chains, have a wide range of applications in various industries. Here are some common industries where motor chains are used:

1. Automotive Industry: Motor chains are extensively used in automotive manufacturing for power transmission in engines, timing systems, and other mechanical components. They ensure precise motion control and synchronization of engine parts.

2. Industrial Machinery: Motor chains are found in a variety of industrial machinery, including conveyor systems, material handling equipment, packaging machines, printing presses, and assembly lines. They facilitate the movement of components and materials, ensuring smooth operation and efficient production.

3. Construction and Mining: Motor chains are used in construction and mining equipment such as excavators, cranes, bulldozers, and conveyor systems. They handle heavy loads and provide reliable power transmission in demanding environments.

4. Agriculture: Motor chains are employed in agricultural machinery such as tractors, combine harvesters, and irrigation systems. They help drive various components and ensure efficient operation in farming and crop production.

5. Material Handling: Motor chains are vital in material handling equipment, including forklifts, hoists, and elevators. They enable the lifting and movement of heavy loads, ensuring precise control and safe operation.

6. Energy and Utilities: Motor chains are used in power generation facilities, such as turbines and generators, to transmit rotational power. They are also found in wind turbines, hydroelectric plants, and other renewable energy systems.

7. Food and Beverage: Motor chains are employed in food processing equipment, including conveyors, mixers, bottling lines, and packaging machines. They ensure efficient and hygienic material handling in the food and beverage industry.

These are just a few examples, and motor chains are utilized in many other industries where power transmission and motion control are critical. Their versatility, durability, and ability to handle high loads make them indispensable in various industrial applications.

editor by CX 2024-04-23