Product Description

|

Infeed Height: |

Customized |

|

Out-feed Height: |

Max Height 10 Meters |

|

Chain Width: |

304.8mm, 406.4mm, 609.6mm |

|

Conveyor Speed: |

Max 60 m/min (customized) |

|

Application: |

Cosmetic/Food/Beverage/Packaging Industry,etc |

|

Advantage: |

We have our own injection modling facory |

|

Delivery: |

30-40 days after downpayement |

|

Warranty: |

1 year (except human factor) |

|

Motor brand: |

SEW or Made in China or customized |

|

Test: |

working 24 hours for testing |

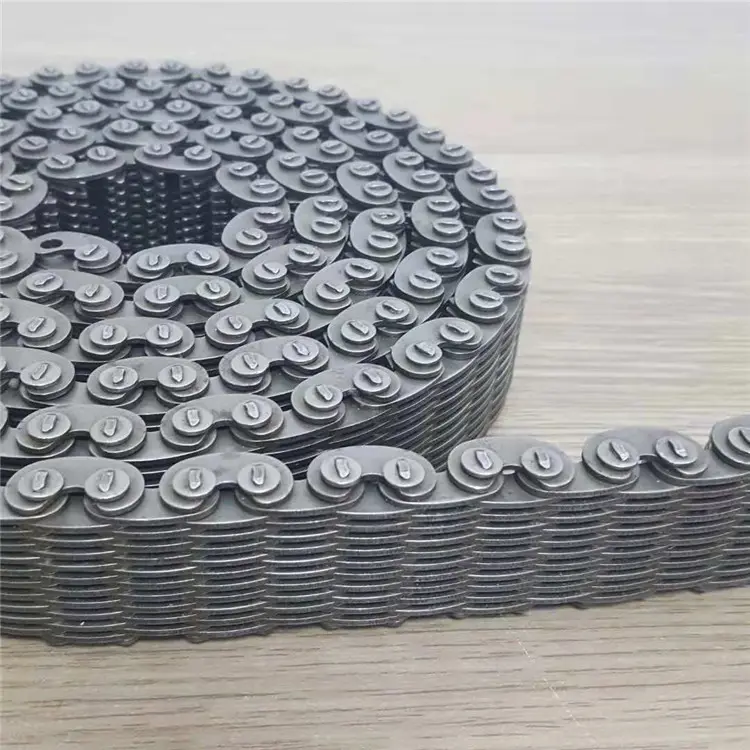

Spiral plastic top chain with anti-skidding chain conveyor system

Spiral conveyor is a lifting conveying equipment, mostly used in packaging, pharmaceutical, papermaking, chemical industry, food industry and other fields.As a lifting transimission system, screw conveyor has played a great role.It not only can transfer things from the low to high conveying,but also up to down transporting.Spiral lifting conveyor is climbing in the form of screw.

Features of spiral conveyor:

1.conveying, lifting and picking up cartons and boxes;

2.saving energy in low cost with high performance;

3.saving floor space;

4.flexible retention time;

5.continuous and sound proofing full automatic production, saving labor cost.

6.easier controls integration

Materials required for support frame:can be made of carbon steel baking paint or 201 stainless steel or 304 stainless steel material, using welding support climbing fuselage, support legs using square pipe cross welding, can make the screw conveyor more stable.

|

Model |

Wide/mm |

Radius/mm |

Weight |

|

|

1873-P-K1250/SS1873-P-K1600 |

320 |

150 |

3.0 |

|

|

1873-P-K2400/SS1873-P-K2400 |

609.6 |

150 |

4.0 |

|

|

1873-P-K1600/SS1873-P-K1600 |

406.4 |

150 |

4.1 |

|

|

1873-P-K2400/SS1873-P-K2400 |

609.6 |

125 |

4.8 |

Gravity roller free spiral conveyor

Free roller spiral conveyor is also 1 of screw vertical lifting conveyor,the frame support can be carbon steel,if you have higher budget,stainless steel frame is better.The roller is cone type stainless steel roller.

Spiral conveyor for cases Features

* Continuous transferring, high efficiency;

* Driven by only 1 motor under height of 10m;

* Can be customized, variety of models;

* Widely application, stable and reliable;

* Easy to operate and maintain.

Plastic flexible chain spiral conveyor

The Spiral Flex Conveyor is a proven reliable concept in vertical conveying. It is designed to conserve valuable floor space. The

Spiral Flex Conveyor transports up or down in a continuous flow. With a speed of 45m/minute and loads up to 10 kg/m the single

lane facilitates a high continuous throughput.

Spiral cooling tower

Modular belt spiral conveyor

For more details, please write to us.

Why Choose US

Q1. Are you trading company or manufacturer?

A: We’re manufacturer. We have our own factory and experienced technicans.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery and delivery time?

A: EXW, FOB, CFR, CIF, DDU, etc.

Generally, it will take7 to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q5. What is your sample policy?

A: We can supply some certain small sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

For more details, please write to us.

| After-sales Service: | Online Support and Supply Conveyor Parts |

|---|---|

| Warranty: | Online Support and Supply Conveyor Parts |

| Structure: | Roller Conveyor |

| Material: | Stainless Steel |

| Material Feature: | Heat Resistant |

| Application: | Chemical Industry, Grain Transport, Power Plant |

| Samples: |

US$ 180/Meter

1 Meter(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do you ensure proper tensioning of a motor chain?

To ensure proper tensioning of a motor chain, the following steps can be followed:

1. Consult Manufacturer Guidelines:

Refer to the manufacturer’s guidelines and specifications for the specific motor chain being used. They often provide recommended tensioning values and procedures.

2. Check Initial Tension:

Ensure that the initial tension of the motor chain is set correctly during installation. This involves adjusting the tension to the manufacturer’s specifications based on the chain length and type.

3. Measure Deflection:

Measure the chain’s deflection to determine if it is within the recommended range. Deflection refers to the amount of vertical movement the chain has when pressure is applied at a specific point.

4. Use Tensioning Tools:

Utilize appropriate tensioning tools to adjust the tension of the motor chain accurately. These tools can help ensure consistent and accurate tensioning across the entire length of the chain.

5. Check Alignment:

Ensure that the motor chain is properly aligned with the sprockets and pulleys it interacts with. Misalignment can cause uneven tension distribution and lead to premature wear and potential failure.

6. Regular Inspection:

Regularly inspect the motor chain for any signs of excessive wear, stretching, or elongation. If any issues are identified, take appropriate action such as adjusting the tension or replacing the chain.

It is important to note that the proper tensioning of a motor chain is crucial for its reliable operation. Improper tension can lead to premature wear, increased noise, and reduced efficiency. Always follow the manufacturer’s recommendations and consult with experienced professionals if necessary.

How do you properly lubricate and maintain a motor chain?

Proper lubrication and maintenance are essential for ensuring the optimal performance and longevity of a motor chain. Here are the steps to properly lubricate and maintain a motor chain:

1. Clean the chain: Before lubricating, clean the motor chain to remove any dirt, debris, or old lubricant. Use a suitable cleaning agent and a brush or cloth to gently scrub the chain. Ensure that the chain is completely dry before proceeding.

2. Choose the right lubricant: Select a lubricant specifically designed for motor chains. Consider factors such as the operating conditions, temperature, and load requirements when choosing the lubricant. Consult the manufacturer’s recommendations or seek professional advice if necessary.

3. Apply the lubricant: Apply the lubricant evenly to the entire length of the motor chain. Use a suitable applicator or a spray bottle to ensure thorough coverage. Pay special attention to the contact points between the chain and the sprockets.

4. Remove excess lubricant: After applying the lubricant, allow it to penetrate the chain for a few minutes. Then, use a cloth or rag to wipe off any excess lubricant. This helps prevent the accumulation of dirt and debris on the chain.

5. Regular inspection: Regularly inspect the motor chain for signs of wear, corrosion, or damage. Look for elongation, cracked plates, damaged pins, or excessive play. If any issues are found, take appropriate action, such as replacing the chain or repairing the damaged components.

6. Tension adjustment: Check the tension of the motor chain regularly. Improper tension can cause excessive wear and reduce the chain’s performance. Follow the manufacturer’s guidelines or consult a professional to ensure proper tensioning.

7. Schedule maintenance: Establish a maintenance schedule for the motor chain. This includes regular cleaning, lubrication, inspection, and any necessary adjustments or replacements. Adhere to the schedule to keep the chain in optimal condition.

By following these steps and maintaining a regular maintenance routine, you can maximize the performance and service life of your motor chain.

What is a motor chain and how is it used?

A motor chain, also known as a power transmission chain, is a mechanical device used to transmit power from a motor or engine to various parts of a machine or system. It consists of a series of interconnected links that form a flexible and durable chain.

Motor chains are commonly used in a wide range of applications, including automotive, industrial machinery, agricultural equipment, and conveyor systems. They play a vital role in transmitting rotational motion and power from the motor to different components such as wheels, gears, sprockets, or pulleys.

Here’s how a motor chain is typically used:

1. Power Transmission: The primary function of a motor chain is to transmit power from the motor to other parts of the system. When the motor rotates, it drives the chain, which in turn drives the connected components, enabling them to perform their intended functions.

2. Speed and Torque Conversion: Motor chains are designed to transmit power at different speeds and convert the torque between the motor and the driven components. By selecting appropriate sprocket sizes and chain lengths, the rotational speed and torque can be adjusted to suit the requirements of the system.

3. Flexibility and Adaptability: Motor chains are flexible and adaptable, allowing them to be used in various orientations and configurations. They can accommodate misalignment, uneven loads, and changes in direction, making them suitable for complex machinery and systems.

4. Maintenance and Lubrication: Proper maintenance and lubrication are essential for the reliable operation of motor chains. Regular inspection, cleaning, and lubrication help reduce friction, wear, and corrosion, ensuring optimal performance and longevity of the chain.

Motor chains come in different sizes, designs, and materials to suit specific applications. Selecting the right chain for a particular system involves considering factors such as load capacity, speed, environment, and compatibility with other components. It is important to follow the manufacturer’s guidelines and industry standards to ensure safe and efficient operation.

editor by CX 2023-10-27