Product Description

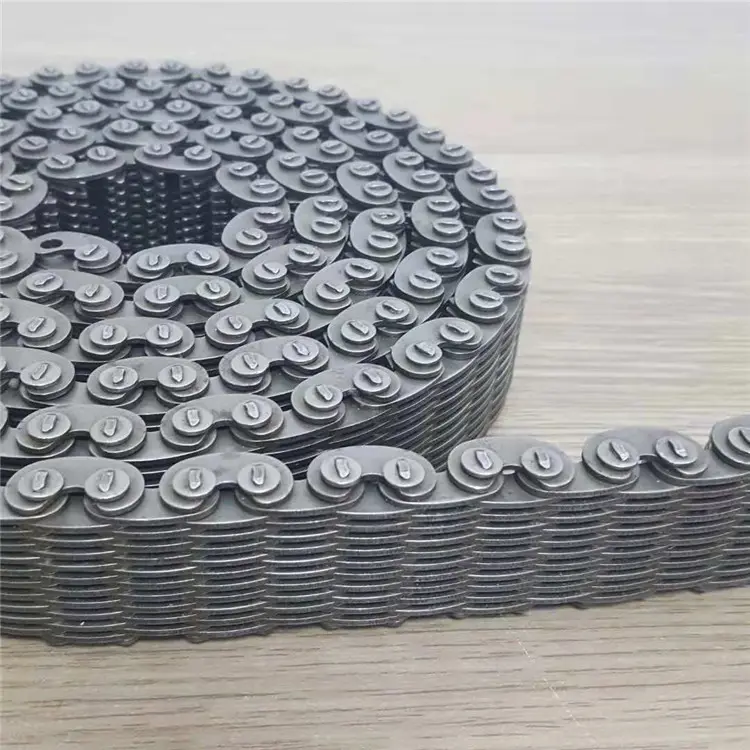

Stainless Steel Roller Chain Sprocket (All Types)

DETAILS ABOUT CZPT CHAIN

Product Description

| Product Name | Chain Sprockets |

| Process | Forging, hobbing, precision machining, etc. |

| Certifications | ISO 9001: 2008, GB/T19001-2000IDT, Test Report |

| Standard | GB1244-85, DIN8187,8188, OEM, ANSI or DIN |

| Surface Treatment | Blacken or Galvanized as You Required |

| Material | Stainless steel, carbon steel, aluminum, copper, brass |

| Heat Treatment | 45 – 55 HRC |

| Packaging | Plastic bag+paper case+wooden pallet |

| Applications | Building Material Shops, Machinery, Industrial, etc. |

More Products

Advantage

DETAILS ABOUT CZPT CHAIN

Exhibition

Certifications

Workshop

Application

Packaging Details & Shipping

FAQ

1. Are you a manufacturer or trade Company?

We are a factory founded in 1997 with a trade team for international service.

2. What terms of payment do you usually use?

T/T 30% deposit and 70% against document, Western Union, L/C at sight

3. What is your lead time for your goods?

Normally 35 days after confirmed order. 30 days could be available in the low season for some items (during May to July), and 45 days during the new year and hot season ( Jan to March).

4. Samples

For customers who need sample confirmation before ordering, please bear in mind that the following policy will be adopted:

1) All samples are free of charge with a maximum value not exceeding USD 100.

2) The courier cost for the first-time sample sending will be charged by the consignee. We will send the samples with freight to be collected. So please inform your account with FedEx, UPS, DHL, or TNT so that we can proceed promptly.

3) The first-time courier cost will be totally deducted from the contract value of the trial cooperation.

| Standard Or Nonstandard: | Standard |

|---|---|

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery |

| Hardness: | Hardened Tooth Surface |

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Customization: |

Available

| Customized Request |

|---|

How do you troubleshoot common issues with motor chains?

Troubleshooting common issues with motor chains involves identifying the root cause of the problem and taking appropriate corrective actions. Here are some common issues that can occur with motor chains and the steps to troubleshoot them:

1. Chain slipping or jumping: If the motor chain slips or jumps on the sprockets, it can indicate insufficient tension, worn-out sprockets, or a damaged chain. Check the tension of the chain and adjust it according to the manufacturer’s recommendations. Inspect the sprockets for signs of wear or damage and replace them if necessary. Additionally, examine the chain for any damaged or worn-out links and replace the chain if needed.

2. Excessive noise: Excessive noise from the motor chain can be caused by various factors such as misalignment, lack of lubrication, worn-out components, or improper tension. Inspect the chain for any misalignment issues and adjust the alignment if necessary. Ensure that the chain is properly lubricated using the recommended lubricant. Check for any worn-out or damaged components and replace them as needed. Adjust the chain tension to the proper specifications.

3. Chain binding or jamming: If the motor chain binds or jams during operation, it can be due to misalignment, debris accumulation, or insufficient lubrication. Check for any misalignment and adjust the alignment of the chain and sprockets if required. Clean any debris or foreign particles that may have accumulated on the chain or sprockets. Ensure proper lubrication of the chain to minimize friction and improve smooth operation.

4. Chain wear and elongation: Excessive chain wear and elongation can lead to poor performance and decreased efficiency. Regularly monitor the chain for signs of wear and measure its elongation using a chain wear gauge. If the wear exceeds the manufacturer’s recommendations, it is advisable to replace the chain with a new one.

5. Insufficient lubrication: Inadequate lubrication can cause increased friction, wear, and premature failure of the motor chain. Check the lubrication system and ensure that the chain is properly lubricated with the recommended lubricant. Adjust the lubrication frequency or method if necessary to ensure optimal lubrication.

When troubleshooting motor chain issues, it is important to refer to the manufacturer’s guidelines and recommendations. If the problem persists or if you are unsure about the appropriate troubleshooting steps, it is recommended to consult a professional or the chain manufacturer for further assistance.

Can a motor chain handle heavy loads?

Yes, motor chains are designed to handle heavy loads in various applications. Here are some factors to consider:

1. Chain Strength: Motor chains are available in different strength ratings, typically measured in terms of their maximum allowable tension or breaking strength. It is important to select a motor chain with a strength rating suitable for the anticipated loads in your application. Chains with higher strength ratings can handle heavier loads.

2. Chain Material: Motor chains are commonly made from high-strength steel or alloy materials that provide excellent durability and load-bearing capacity. The choice of material depends on the specific application requirements, including the expected load, environmental conditions, and any regulatory standards.

3. Chain Design: Motor chains designed for heavy-load applications often have robust construction features to enhance their load-carrying capabilities. These may include larger pitch sizes, thicker plates, hardened components, and precision manufacturing. The design ensures that the chain can withstand the forces and stresses associated with heavy loads.

4. Lubrication: Proper lubrication is essential for motor chains handling heavy loads. It helps reduce friction and wear, ensuring smooth operation and extending the chain’s service life. Adequate lubrication also prevents overheating and corrosion, which can negatively impact the chain’s load-carrying capacity.

5. Sprocket Design: The sprockets that engage with the motor chain also play a crucial role in handling heavy loads. Sprockets should be designed to evenly distribute the load across the chain and provide reliable engagement. Robust and properly sized sprockets ensure that the chain can effectively transmit the heavy loads without excessive wear or failure.

When considering a motor chain for heavy-load applications, it is important to consult the manufacturer’s specifications and guidelines. They can provide detailed information on the chain’s load-carrying capacity, including factors such as tensile strength, working load limits, and recommended safety factors. Proper chain selection, regular maintenance, and adherence to load limitations are key to ensuring safe and efficient operation under heavy loads.

How does a motor chain differ from a regular chain?

A motor chain, also known as a power transmission chain, differs from a regular chain in terms of its design and purpose. Here are the key differences:

1. Load Capacity: Motor chains are specifically designed to handle higher loads compared to regular chains. They are built to transmit power and motion between different components in mechanical systems.

2. Precision and Accuracy: Motor chains often have precise tooth profiles or roller systems that ensure accurate positioning and synchronization of components. This is important in applications such as engines, where precise timing is critical.

3. Durability and Strength: Motor chains are built to withstand heavy loads, high speeds, and continuous operation. They are constructed using high-quality materials and advanced manufacturing techniques to ensure durability and strength.

4. Lubrication and Maintenance: Motor chains may require specific lubrication to reduce friction and wear, ensuring smooth operation. Regular maintenance, such as periodic inspection and lubrication, is important to keep the chain in optimal condition.

5. Application-Specific Design: Motor chains are designed for specific applications, such as power transmission in engines, conveyor systems, or lifting equipment. They are engineered to meet the unique requirements of these applications, considering factors such as load capacity, speed, environment, and operational conditions.

It’s important to note that while motor chains are designed for specific applications, they may have similarities with regular chains in terms of basic construction and functionality. However, motor chains are engineered to handle higher loads, provide precise motion transmission, and ensure reliable performance in demanding industrial settings.

editor by CX 2023-07-27